The Electrocube 916D series includes rugged, non-inductively wound metallized audio capacitors. Proudly made in the U.S. with proprietary techniques, it offers high frequency operation, high current and low ESR in a miniature package. The 916D series is part of a designated line of capacitors specially designed and optimized for high-end audio applications subject to AC and pulsing signals. An excellent replacement for electrolytic capacitors, it is able to handle high surge currents without degrading. Audio engineers prefer the 916D series high-grade materials, design and manufacturing for professional, commercial stage and studio applications.

Dielectric voltage test

DC life test

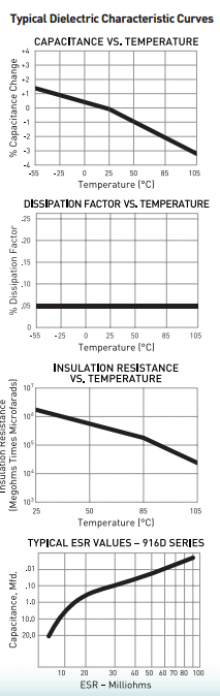

Dissipation factor

Dielectric absorption

Acceptance criteria