There is a great deal of confusion still existing in the minds of many engineers regarding metallized dielectric capacitors. This is unfortunate because this confusion has resulted in many cases in the exclusion of a most valuable tool from many circuit designs. These should not be, and there is nothing any more mysterious about the proper application of a metallized dielectric capacitor than there is in a non-metallized unit.

A close examination of the basic aspects of a metallized dielectric should help to clear up this unnecessary confusion.

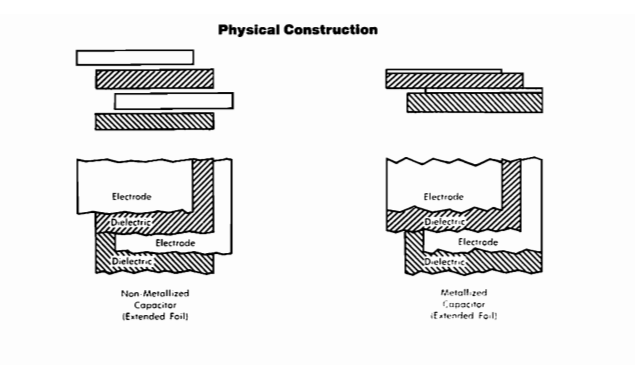

The construction of a metallized dielectric capacitor is quite similar to that of a non-metallized design except for slight differences in electrodes and end terminations.

The electrodes in a non-metallized design are separate sheets of metal foil wound with the sheets of dielectric. These electrode sheets extend alternately out each end of the roll beyond the dielectric and provide a mass of all metal material to which leads are then attached by soldering or welding.

The metal electrodes of the metallized design are deposited from a melted or liquified state directly onto the surface of the dielectric. Provisions are made to provide one end of each sheet with a margin. Two sheets of metallized dielectric are positioned properly relative to a right and left margin and wound into a roll. Because the dielectric material is also present at each end of the roll along with the metal electrode material, direct attachment of the leads is not generally done.

The end terminations of the metallized unit are accomplished by applying a finely divided molten metal spray to the capacitor roll ends to make initial contact with the electrode material. Leads are then attached to this metal spray.

Volumetric Efficiency

From the foregoing, the volumetric advantage of a metallized design is self-evident due to the physical reduction of total electrode material and air film. This advantage is more evident and becomes more pronounced as the capacitance rating increases.

At the smaller capacitance ratings, there is very little advantage evident because the end terminations, casings, and end seals form a disproportionate part of the total volume for a practical capacitor and are approximately the same for both types of units. For instance, the chart below compares the approximate volumetric ratio for various values of capacitance between the metallized and non-metallized designs. All units are wrap-and-fill style, 200 voe rated, Mylar dielectric.

The volume of the metallized design is set as unity, and the volume of the non-metallized design is then expressed as an equivalent ratio.

The exact microfarad values where the cost of the metallized and non-metallized unit equates will vary with voltage, dielectric, and configuration.